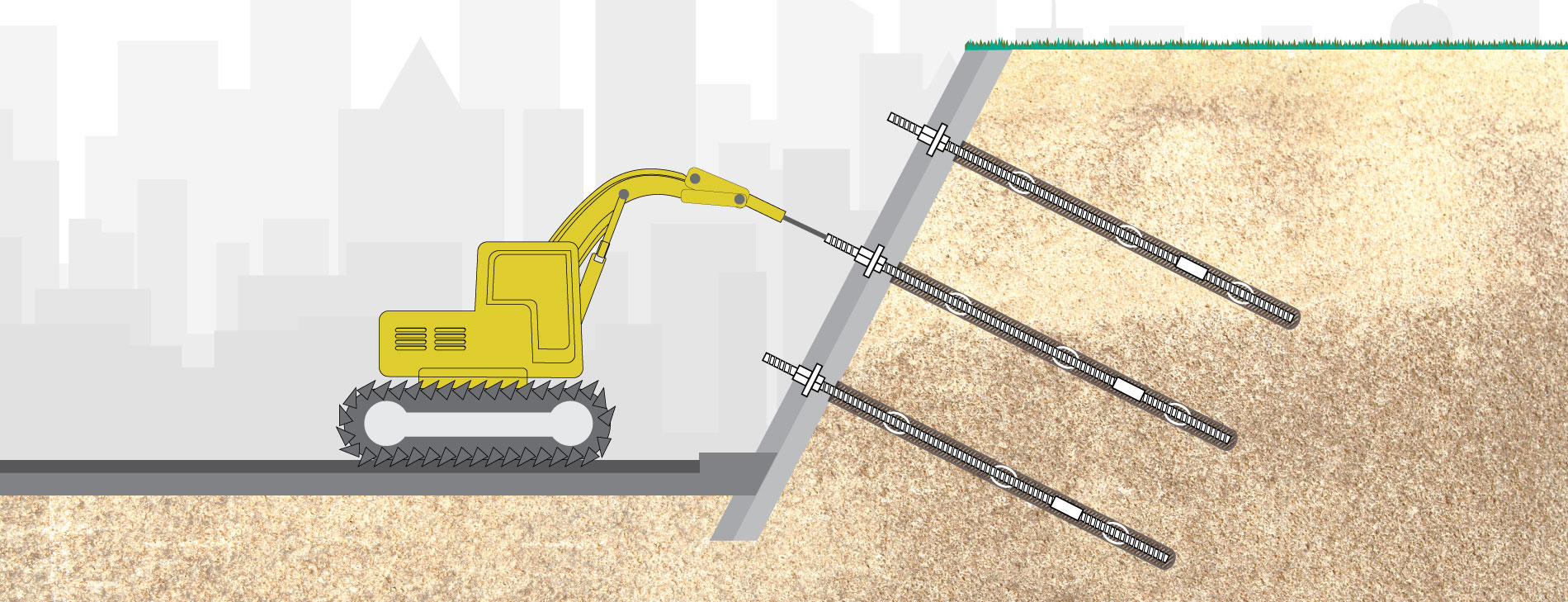

Soil nailing is an economical technique used to stabilize existing slopes and to construct retaining walls from the top down. This soil reinforcement process uses steel tendons which are drilled and grouted into the soil to create a composite mass similar to a gravity wall.

Micropiles, also known as minipiles, pin piles, needle piles, and root piles, are a deep foundation element constructed using high-strength, small-diameter steel casing and/or threaded bars.

Anchoring increases the stability and durability of the construction by transferring both tension and shear forces. These structures are also known as ground anchors or earth anchors, and they come in different forms and sizes that can be used to support buildings or civil engineering and other structures.

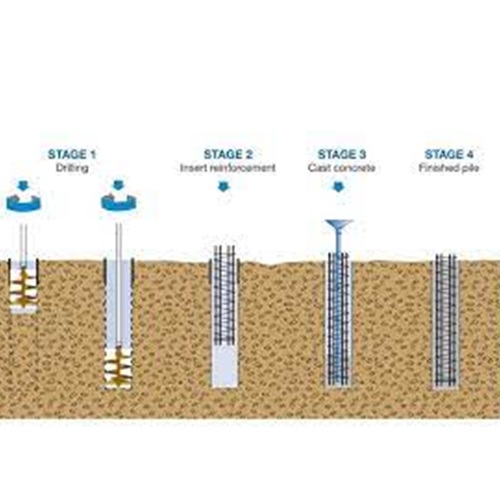

Concrete Piling – Concrete piles come with Reinforced Cement Concrete (RCC). You can see this piling in heavy load-bearing structures such as bridges, high-rise buildings, and retaining walls. These piles also withstand high compressive and tensile forces.

Sheet piles are sections of sheet steel with interlocking edges (or clutches) that are driven into the ground to provide earth retention and excavation support. Vibratory hammers are often used to install sheet piles, although if soils are too hard/dense impact hammers can be used.

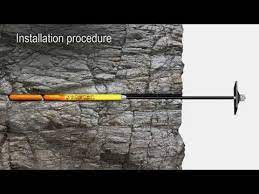

A rock bolt is a long anchor bolt, for stabilizing rock excavations, which may be used in tunnels or rock cuts. It transfers load from the unstable exterior to the confined (and much stronger) interior of the rock mass.

Piling is, therefore, the process of making or drilling poles. Piling rigs are mainly used to drill in silty clay, sandy soil, clay, etc. In addition, it is vastly used in diaphragm walls, foundation projects, foundation reinforcement, and other cast-in-place piles.

Rock bolt installation involves drilling, inserting, anchoring, and tensioning the bolts. The drilling process should follow the design specifications for the borehole diameter, length, orientation, and spacing.

Grouting, in the context of construction, is a specialised process that involves injecting a fluid-like material into gaps, voids, or spaces within structures. Its purpose is to improve structural integrity, enhance load-bearing capacity, and provide stability to various elements of a construction project.

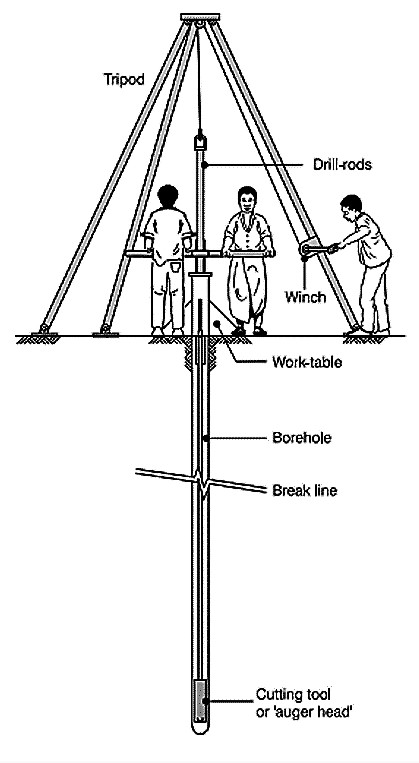

Manual drilling refers to several drilling methods that rely on human energy to construct a borehole and complete a water supply. The various techniques can be used in areas where formations are quite soft and groundwater is relatively shallow. Manual drilling can provide safe drinking water.

A drilling machine is a tool used for drilling holes in various materials, such as metal, ceramic wood, or plastic. It can be either portable or stationary.

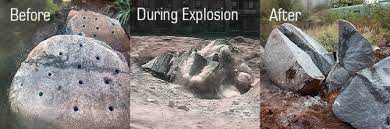

Drilling and blasting is the controlled use of explosives and other methods, such as gas pressure blasting pyrotechnics, to break rock for excavation. It is practiced most often in mining, quarrying and civil engineering such as dam, tunnel or road construction. The result of rock blasting is often known as a rock cut.

Shotcreting is a process that involves spraying or depositing mortar made from very fine concrete on a prepared surface. The spray velocity is very high, and the material deposited on the surface is called shotcrete. It has different names depending on the country, like Nucrete, Torkrete, Guncrete, Blastcrete, etc.

Gabions feature a metal cage that houses stones or rocks. They are used to create retaining walls by offering a hard and stable structure. Gabions work like most other types of retaining walls by offering a stable structure that holds the soil behind them in place.

With a concrete ditch lining system, you can permanently control erosion in ditches both big and small. A permanent rather than temporary solution, HYDROTEX fabric-formed concrete can be used in virtually any trapezoidal ditch, including drainage ditches, irrigation ditches, and stormwater ditches.

A weep brick also referred to as a weep hole, is a small opening that lets water drain from a building. The weeps are positioned on the object's bottom to allow drainage; these holes must be sufficiently large to withstand surface pressure.

The Masonry Protection Cream provides long lasting protection from water penetration and the spread of damp in masonry and brickwork by filling the porous voids within the substrate without blocking them. This allows the masonry to release trapped moisture and to 'breathe', preventing moisture build up

A shear wall is a general term for a wall that is designed and constructed to resist racking from forces such as wind using masonry, concrete, cold-formed steel, or wood framing. Shear walls significantly reduce the sway of a structure to reduce damage to the structure and its contents.